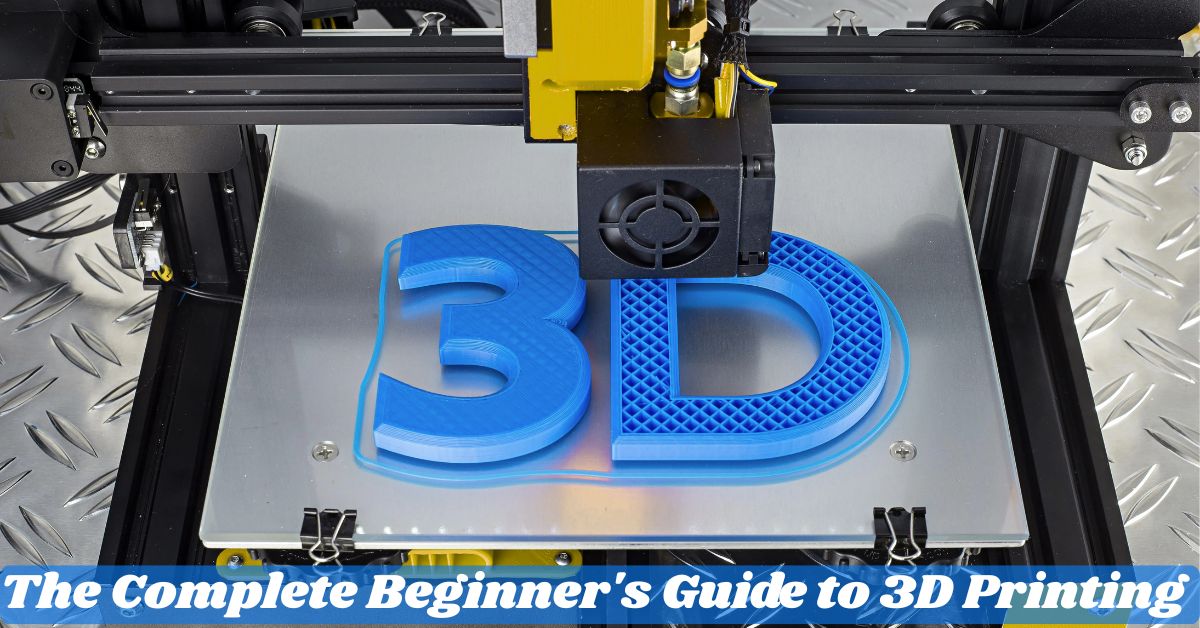

Stepping into the world of 3D printing opens doors to unlimited creativity and innovation. Whether you’re a curious hobbyist or aspiring maker, this technology transforms digital designs into physical reality with remarkable precision.

This comprehensive guide covers everything from basic concepts to practical tips for your first successful prints. No prior experience needed just bring your imagination and let’s dive into the exciting realm of additive manufacturing together!

What Is 3D Printing?

3D printing is an additive manufacturing process that creates three-dimensional objects layer by layer. Unlike traditional manufacturing that cuts away material, 3D printing adds material precisely where needed.

This technology transforms digital designs into physical objects using various materials. The process starts with a digital 3D model and ends with a real-world object you can hold in your hands.

The History of 3D Printing

The concept of 3D printing dates back to the 1980s. Chuck Hull invented the first 3D printing technology called stereolithography in 1984. Early printers were massive, expensive machines used primarily in industrial settings.

The technology remained largely inaccessible to everyday consumers for decades. Recent years have seen dramatic improvements in affordability and accessibility.

Some Key Historical 3D Printing Milestones:

- 1984: Chuck Hull invents stereolithography (SLA)

- 1988: Scott Crump patents Fused Deposition Modeling (FDM)

- 1992: First SLA 3D printer machine is sold

- 2005: RepRap project launches, aiming to create self-replicating 3D printers

- 2009: FDM patents expire, leading to a boom in affordable desktop printers

- 2013: 3D printing enters mainstream awareness

- 2015: Carbon introduces CLIP technology for faster printing

- 2020: 3D printing proves crucial for rapid production during global pandemic

The Technology Behind 3D Printing

All 3D printers follow the same basic principle: building objects layer by layer. The printer reads instructions from a digital file that describes the object’s dimensions. Special software slices the model into hundreds or thousands of horizontal layers.

The printer then creates each layer, one atop another, until the object is complete. Different technologies use different methods for creating these layers.

How 3D Printing is Affecting Industries Around the Globe?

The Economic Impact

3D printing is revolutionizing manufacturing economics across multiple sectors. Companies can now prototype products quickly without expensive tooling. Small businesses can compete with larger manufacturers by creating custom products on demand.

The technology has reduced production costs for complex parts in aerospace and automotive industries. Local manufacturing becomes more feasible, potentially reducing shipping and import expenses.

Environmental Considerations

3D printing offers several environmental benefits when implemented thoughtfully. The technology can reduce material waste compared to subtractive manufacturing. Parts can be printed using exactly the material needed with minimal scrap.

Local production reduces transportation emissions and packaging waste. However, some printing materials like ABS plastic create potentially harmful fumes. Electricity consumption and plastic waste remain environmental concerns for the industry.

Social Implications

The democratization of manufacturing through 3D printing has profound social impacts. Medical applications improve quality of life with customized prosthetics and implants. Educational access to 3D printing inspires a new generation of makers and engineers.

Remote communities can produce needed items locally instead of waiting for shipments. Humanitarian organizations use the technology for rapid disaster response needs.

Future Prospects

The future of 3D printing looks incredibly promising with ongoing innovations. Experts predict continued improvements in print speed and material options. Multi-material printing will become more accessible and affordable.

Metal printing will move from industrial to desktop environments. Bioprinting human tissues and organs may revolutionize medicine. Construction-scale printing could transform how we build homes and infrastructure.

What Are Some Common 3D Printing Applications?

The Medical Field

The medical industry has embraced 3D printing for numerous life-changing applications:

- Custom prosthetic limbs at a fraction of traditional costs

- Patient-specific surgical guides improving procedure accuracy

- Anatomical models for surgical planning and education

- Dental applications including crowns, bridges, and aligners

- Bioprinting research for tissue and organ replacement

- Customized hearing aids and other medical devices

Aerospace Engineering

Aerospace companies utilize 3D printing to create:

- Lightweight yet strong structural components

- Complex geometries impossible with traditional manufacturing

- Consolidated parts that reduce assembly requirements

- Prototypes for aerodynamic testing

- Tooling and fixtures for aircraft assembly

- Replacement parts for older aircraft models

Customized Gadgets and Accessories

Personal customization has flourished with 3D printing:

- Smartphone cases tailored to individual preferences

- Custom gaming accessories and controllers

- Personalized jewelry and fashion items

- Unique decorative objects for home décor

- Replacement parts for household items

- Custom camera mounts and photography accessories

Home Improvement

DIY enthusiasts leverage 3D printing for:

- Custom cabinet handles and drawer pulls

- Specialized wall mounts and brackets

- Replacement parts for appliances

- Decorative light fixtures and lamp shades

- Custom plumbing fixtures and adapters

- Organizational tools and storage solutions

Educational Tools

Schools and educators use 3D printing to create:

- Tactile learning aids for various subjects

- Anatomical models for biology classes

- Molecular structures for chemistry education

- Historical artifacts reproductions

- Engineering project components

- STEM curriculum enhancement tools

READ THIS BLOG: Software huzoxhu4.f6q5-3d: An In-Depth Exploration of a Mysterious Digital Entity

The Material Science Behind 3D Printing

Material choice drastically affects print quality, durability, and application. Thermoplastics remain the most common materials for beginner-friendly printers. PLA (Polylactic Acid) offers biodegradability and ease of use.

ABS (Acrylonitrile Butadiene Styrene) provides durability but requires ventilation. PETG combines strength with ease of printing. TPU allows for flexible, rubber-like prints. Professional printers can use resins, metals, ceramics, and even concrete.

Some 3D Printing Key Terms

Print Quality Terms

- Layer height: The thickness of each printed layer (smaller = finer detail but slower prints)

- Infill: The internal density of a printed object (higher percentage = stronger but heavier)

- Shell thickness: The outer wall thickness of a print

- Supports: Temporary structures that hold up overhanging features

- Bridging: Printing horizontal spans between two raised points

- Warping: Undesired curling of the print’s base due to cooling issues

Calibration and Tuning Terms

- Bed leveling: Ensuring the print surface is perfectly parallel to the print head

- Extrusion multiplier: Adjusts how much material is pushed through the nozzle

- Retraction: When the printer pulls filament back slightly to prevent oozing

- Flow rate: Speed at which filament is extruded

- Temperature tower: A test print to determine optimal temperature settings

- Z-offset: Fine adjustment of nozzle distance from the print bed

Advanced Feature Terms

- Auto bed leveling: Sensors that automatically map the print bed surface

- Direct drive: Extruder mounted directly above the hot end

- Bowden setup: Extruder separated from hot end with a tube between them

- Dual extrusion: Printers with two or more separate nozzles

- Silent stepper drivers: Advanced motor controllers for quieter operation

- Linear advance: Firmware feature improving corner quality

Safety Terms

- Thermal runaway protection: Safety feature preventing overheating

- Enclosure: Cover surrounding printer to maintain temperature and contain fumes

- HEPA filter: Air filtration system removing potentially harmful particles

- UL certification: Safety standard verification for electrical components

- Emergency stop: Button to immediately halt all printer operations

- Power loss recovery: Feature allowing prints to resume after power outage

Firmware and Update Terms

- Marlin: Popular open-source firmware for 3D printers

- OctoPrint: Remote management software for printer control

- G-code: The instruction language that tells printers how to move

- Firmware update: Process of installing newer software on your printer

- Bootloader: Software component allowing firmware updates

- Configuration.h: File containing printer-specific settings in Marlin

The Types of 3D Printing

Fused Deposition Modeling (FDM)

FDM is the most common and beginner-friendly 3D printing technology. The process works by melting thermoplastic filament through a heated nozzle. The printer deposits material layer by layer onto a build platform.

FDM printers offer an excellent balance of affordability and capability. This technology uses the widest range of available materials. Most consumer-grade printers use this method.

SLA (Stereolithography or “Resin Printing”)

SLA creates objects using light-sensitive liquid resin and a light source. A laser or projected light cures each layer of resin precisely. This technology produces extremely detailed prints with smooth surfaces.

SLA prints require post-processing in chemical baths. Resin printing requires more careful handling of materials. These printers have become increasingly affordable for hobbyists.

SLS (Selective Laser Sintering)

SLS uses a laser to fuse powdered material layer by layer. This technology can create complex geometries without support. SLS works with various materials including nylon, metals, and ceramics.

The unsintered powder acts as support during printing. This technology remains primarily industrial due to cost. Consumer SLS printers are emerging but remain expensive.

Types of 3D Printing Software

CAD Software

Computer-Aided Design software allows you to create 3D models from scratch:

- Fusion 360: Powerful modeling software with free options for hobbyists

- TinkerCAD: Browser-based, beginner-friendly design tool

- Blender: Free open-source software with powerful modeling capabilities

- FreeCAD: Open-source parametric modeling software

- OnShape: Professional cloud-based CAD with free tier for hobbyists

Slicing Software

Slicing programs convert 3D models into printer-readable instructions:

- Cura: Popular free slicer with extensive printer compatibility

- PrusaSlicer: Feature-rich open-source slicer

- Simplify3D: Premium slicer with advanced control features

- ChituBox: Popular for resin printing preparation

- IdeaMaker: Free slicer with optimization features

Remote Interfacing Software

These programs allow you to control your printer remotely:

- OctoPrint: Most popular remote management solution

- Repetier-Server: Monitor multiple printers simultaneously

- AstroPrint: Cloud-based printer management

- Duet Web Control: Web interface for Duet board equipped printers

- Klipper: Advanced firmware enabling faster printing speeds

How to Choose a 3D Printer for Beginners?

Step 1: Establish A Budget

Setting a realistic budget is your first priority. Entry-level printers start around $200-300. Mid-range options with better features cost $300-600. Premium beginner-friendly models range from $600-1000.

Consider ongoing costs for filament and maintenance. Remember that the cheapest option isn’t always the most economical long-term. Factor in reliability and support when budgeting.

Step 2: Choose FDM First

For beginners, FDM technology offers the gentlest learning curve. FDM materials are affordable and widely available. The printing process is easier to understand and troubleshoot.

Maintenance and safety requirements are more straightforward. You can upgrade to other technologies later as your skills develop. Most online communities focus on helping FDM users.

Step 3: Choose the Right Features

Look for these important features in your first printer:

- Heated bed: Essential for printing materials beyond PLA

- Build volume of at least 220x220x250mm for versatility

- Automatic bed leveling to simplify setup and maintenance

- Direct drive extruder for more reliable printing

- 32-bit mainboard for better performance and quieter operation

- Filament runout sensor to prevent failed prints

- Removable flexible build plate for easier print removal

Step 4: Additional Considerations

Choose Exceptional Software Compatibility

Your printer should work with popular slicing software. Look for models with good profiles in Cura for PrusaSlicer. Avoid printers requiring proprietary software only. Check if the printer accepts standard G-code files.

Ensure firmware updates are regularly available. Consider whether the printer supports OctoPrint for remote control.

Choose Positive Reviews and an Established Community

Research community feedback about reliability and performance. Look for printers with active user groups and forums. Check YouTube for setup and troubleshooting videos. A strong community means better support when problems arise.

Established brands typically have better documentation and resources. Consider how long the printer model has been on the market.

Choose Warranty Details and After-Sales Support

Check warranty duration and what it covers. Research the company’s reputation for honoring warranties. Consider the availability of replacement parts. Look for companies with responsive customer service.

US-based support can simplify troubleshooting in North America. Some companies offer extended support through premium programs.

The Best 3D Printers for Beginners

Based on 2025 market conditions, these printers offer excellent value for beginners:

- Prusa Mini+: Perfect balance of quality and affordability

- Creality Ender 3 S1: Feature-packed with excellent community support

- Elegoo Neptune 4 Pro: Great performance with auto bed leveling

- Anycubic Kobra 2: User-friendly with excellent print quality

- Bambu Lab X1: Premium option with exceptional ease of use

ALSO READ THIS BLOG: SFM Compile: A Guide for Users and Developers

Share Your Thoughts on 3D Printing

The 3D printing community thrives on collaboration and shared knowledge. Join online forums like Reddit’s r/3Dprinting. Share your successful prints and learning experiences. Ask questions when you encounter problems.

Contribute to open-source projects and model repositories. Help others who are newer to the hobby than yourself. The community aspect enhances the 3D printing experience tremendously.

Frequently Asked Questions

What’s the easiest material to start printing with?

PLA (Polylactic Acid) is ideal for beginners with its low printing temperature, minimal warping, and biodegradable composition. It comes in countless colors and is forgiving of minor setting mistakes.

How much does it cost to run a 3D printer?

Electricity costs pennies per hour while filament runs $20-30 per kilogram. A typical hobbyist spends $5-15 monthly on materials and occasional replacement parts like nozzles.

How difficult is 3D printer maintenance?

Basic maintenance is straightforward: clean the build plate, lubricate rails, and change nozzles occasionally. Most preventative tasks require basic tools and plenty of tutorials exist online.

Can I make money with a 3D printer?

Yes, sell custom prints on Etsy, offer local printing services, create designs for marketplaces like Cults3D, or produce educational content about 3D printing on platforms like YouTube.

Is 3D printing safe for home use?

FDM printing with PLA is generally safe in ventilated areas. Use thermal runaway protection, monitor initial prints, and follow manufacturer guidelines for complete safety.

Conclusion

The world of 3D printing offers boundless potential for creativity, problem-solving, and innovation right from your desktop. With today’s user-friendly technology and supportive online communities, there’s never been a better time to begin your maker journey.

Start with quality basics, embrace the learning process, and don’t fear mistakes; they’re valuable stepping stones. As you grow, your skills will unlock capabilities once reserved for industrial facilities. Welcome to the additive manufacturing revolution where you’re limited only by imagination!

Jerry is a seasoned SEO expert with a passion for content writing, keyword research, and web development. He combines technical expertise with creative strategies to deliver exceptional digital solutions.